Knowing the properties of the plastics used to make the components and parts of your devices is essential to being able to produce a reliable, safe and high-performance product.

We perform tests to verify the properties of plastic materials according to the following standards:

TRACKING TEST

Test used to check the surface resistance of solid insulating materials caused by electrical stress.

GLOW WIRE TEST – IEC/EN 60695-2-10

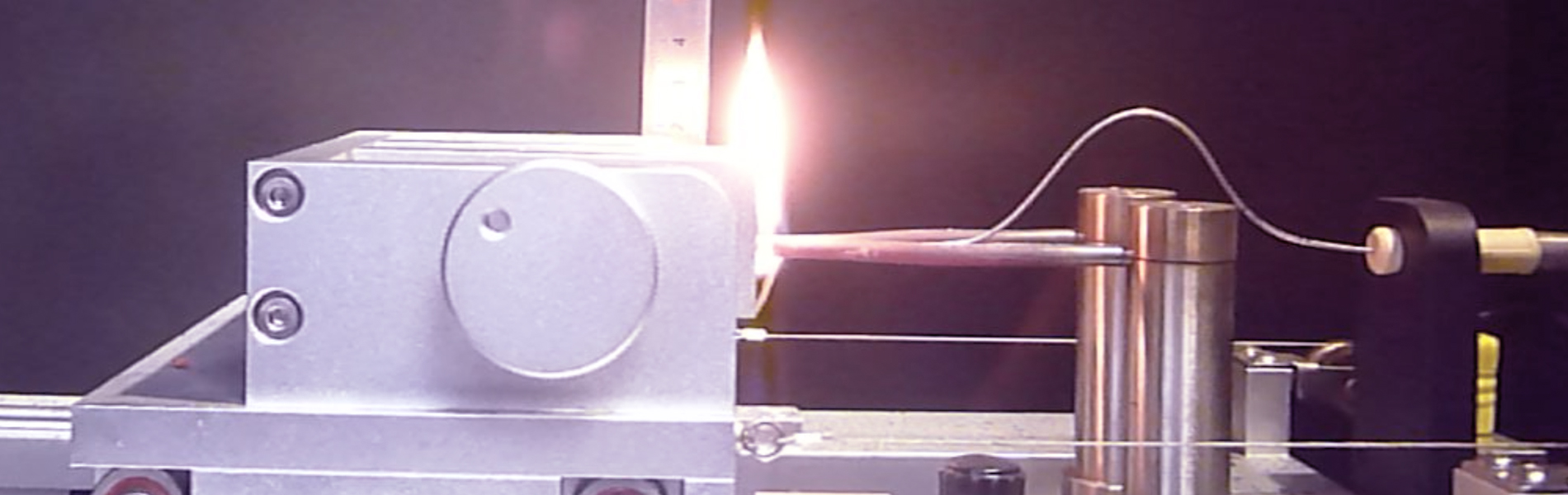

The glow wire test is a test used to simulate the effect of thermal stress that may originate in electronic devices in order to assess the fire hazard using a simulation technique.

The plastic material comes into contact with the glow wire for a specific time and the suitability of the sample is assessed through a series of measurements and observations.

BALL PRESSURE TEST – EN 6069510-2

The test checks insulating materials used in electrical equipment for dimensional stability under abnormal heat stress.

The sample is placed on the base of a steel cylinder and the ball pressure device is placed on the material. This is then all placed inside an oven at a specific temperature. At the end of the specified period, the material is removed and cooled and then, the diameter of the ball impression is measured, which must not exceed specific parameters.

NEEDLE FLAME TEST – IEC 60695-2-2 and IEC 60695-11-5

This test is used to assess the flammability class of a plastic material by simulating the effect of small flames on a test specimen for a specified time.